In the world of heavy machinery and transport, reliability is everything. Trucks and trains are the backbone of freight and logistics industries, and their performance depends heavily on one vital engine component — the crankshaft. When this component fails, it can bring an entire operation to a standstill. That’s where truck and train crankshaft repairs come in — offering a cost-effective and efficient solution to restore your engines and keep your fleet running smoothly.

This guide explores the importance of professional crankshaft repair, the signs of wear and damage, repair techniques, and why trusting specialists is essential for the long-term health of your vehicles.

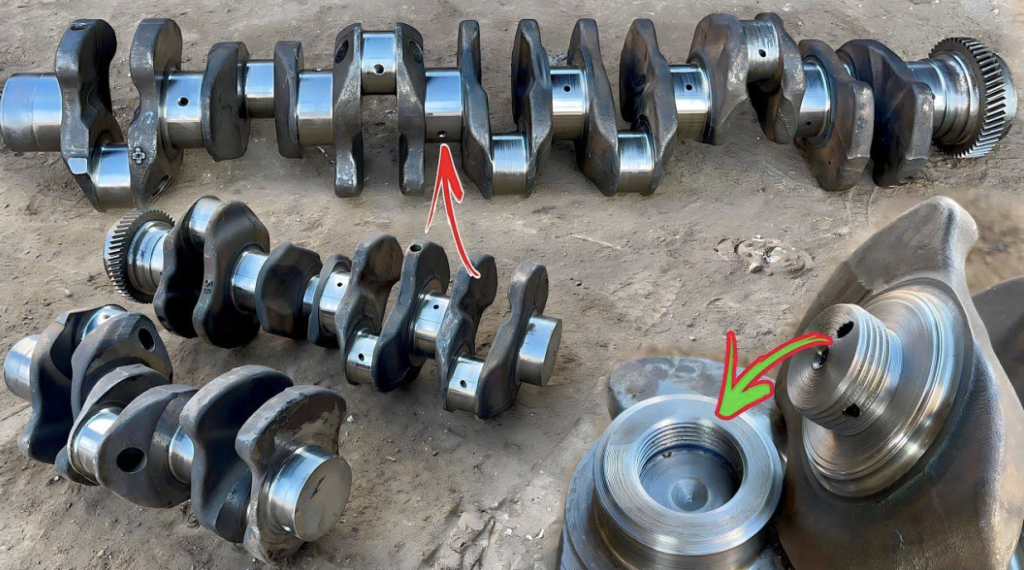

Understanding the Role of the Crankshaft

The crankshaft is the heart of any combustion engine, converting the linear motion of pistons into the rotational force that powers your vehicle. In heavy-duty trucks and locomotives, this component endures extreme loads and high operating pressures daily. Even a small defect in the crankshaft can lead to vibration, loss of power, or complete engine failure.

Regular maintenance and truck and train crankshaft repairs ensure that these vital components stay in top condition, helping operators avoid costly downtime and engine replacements.

Common Causes of Crankshaft Damage

Crankshafts are engineered to withstand immense stress, but over time, wear and tear can take their toll. Here are some of the most common causes of crankshaft damage in trucks and trains:

- Oil Starvation – Lack of lubrication causes friction and heat buildup, leading to surface scoring and bearing failure.

- Fatigue Cracks – Repeated load cycles create micro-cracks that can grow and lead to catastrophic breakage.

- Improper Maintenance – Skipping oil changes or ignoring unusual noises accelerates wear.

- Overheating – Excessive heat can distort or warp the crankshaft, affecting balance and alignment.

- Bearing Failure – Damaged or misaligned bearings put uneven stress on the crankshaft journals.

By identifying these issues early, technicians can perform truck and train crankshaft repairs before the damage becomes irreparable.

The Crankshaft Repair Process

Modern crankshaft repair is a precise and technical process that involves advanced tools and expertise. Let’s take a look at how professionals bring damaged crankshafts back to life:

- Inspection and Damage Assessment

Technicians begin with a comprehensive visual and dimensional inspection using micrometers, magnetic particle testing, and crack detection. This determines whether the crankshaft can be repaired or must be replaced.

- Grinding and Polishing

Worn journals are ground down to remove imperfections, followed by precision polishing to achieve the correct surface finish and oil clearance. This step restores balance and ensures smooth operation.

- Welding or Metal Spraying

If there are deep grooves or cracks, the surface may be rebuilt using welding or metal spray techniques. These repairs are then machined to exact specifications.

- Balancing and Alignment

After machining, the crankshaft is dynamically balanced to eliminate vibration and ensure even rotation. Proper alignment ensures smooth engine operation and longer bearing life.

5.Final Quality Testing

Before installation, the crankshaft undergoes stringent quality checks, including hardness testing, run-out measurements, and surface finish evaluation.

This meticulous process ensures that truck and train crankshaft repairs meet OEM (Original Equipment Manufacturer) standards, extending the lifespan of your engines and enhancing performance.

Benefits of Professional Crankshaft Repairs

Choosing expert repair services over replacements offers numerous advantages:

- Cost Efficiency

A complete crankshaft replacement can be expensive, especially for large engines. Repairing and reconditioning the existing component significantly reduces costs without compromising quality.

- Reduced Downtime

With expert truck and train crankshaft repairs, you can have your equipment back in service quickly. Many repair facilities offer express or on-site services for fleet operators.

- Extended Engine Life

A precisely repaired crankshaft restores optimal performance, reduces vibration, and enhances the longevity of the entire engine assembly.

- Sustainability

Repairing instead of replacing helps reduce waste and supports sustainable industrial practices — an increasingly important factor for transport companies today.

Signs Your Crankshaft May Need Repair

It’s crucial to detect crankshaft problems early to prevent costly damage. Watch for these warning signs in your vehicles:

- Unusual engine knocking or vibrations

- Loss of power or efficiency

- Low oil pressure or metal particles in oil

- Difficulty starting the engine

- Excessive exhaust smoke

If you notice any of these symptoms, it’s time to schedule truck and train crankshaft repairs before a minor issue becomes a major breakdown.

Why Choose Specialists for Heavy-Duty Crankshaft Repairs

Truck and train engines operate on an entirely different scale compared to passenger vehicles. Their crankshafts are larger, heavier, and require highly specialised tools and skills to repair. Certified technicians who specialise in heavy diesel and locomotive engines understand the tolerances, materials, and balance required for these complex systems.

Professional repair centres also offer:

- CNC precision machining

- Dynamic balancing and crack detection equipment

- On-site removal and installation support

- OEM-compliant repair documentation

Choosing a reputable specialist ensures your crankshaft is repaired to the highest industry standards, guaranteeing durability and performance.

Preventive Maintenance Tips for Longevity

After completing truck and train crankshaft repairs, regular maintenance plays a key role in preventing future issues. Here’s how to keep your crankshafts in top shape:

- Maintain Proper Lubrication: Use high-quality oil and change it at recommended intervals.

- Monitor Engine Temperature: Overheating can lead to metal fatigue and warping.

- Check Bearings Regularly: Replace them if signs of wear appear.

- Balance and Alignment: Schedule routine balancing to prevent vibration damage.

- Follow Manufacturer Guidelines: Stick to OEM service recommendations for optimal results.

Proactive care helps extend the lifespan of your crankshaft and reduces costly unplanned repairs.

Final Thoughts

A damaged crankshaft can spell disaster for your fleet, but with professional truck and train crankshaft repairs, you can restore performance, save money, and extend the life of your engines. Investing in expert repair services ensures your vehicles remain reliable, efficient, and ready for the road or rail.

Whether you operate a logistics company or manage a railway maintenance team, choosing specialists for crankshaft repair is a smart move that keeps your fleet moving — efficiently and safely.