Electricity has been used in industries from a long time, and now no industry can survive without proper supply of electricity. Smooth and regular supply of electricity is needed for delivery of the best performance of equipment installed in an industry, and for this reason, it becomes inevitable to take the best care of the high voltage electrical system of an industry.

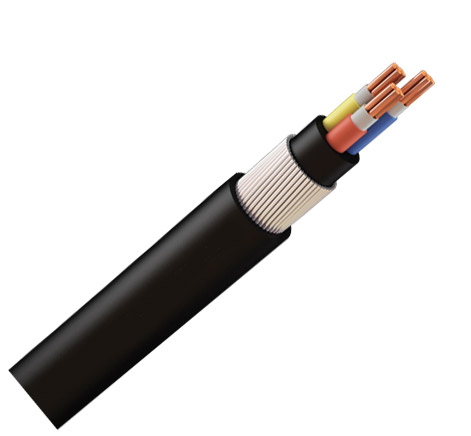

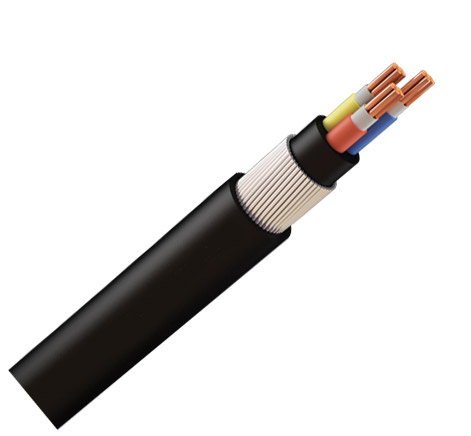

The cables installed in an industrial electrical network are an important component as they are the one that carry the thousands of voltage with them and take them to different points in the industry. Keeping the high voltage cable of a network protected should be the primary goal while taking care of the electrical networks. For this reason, high grade cable accessories are used so that they could keep them stress free and protected from external, as well internal threats.

The industrial electrical supply contains electricity of thousands of volts; hence the electrical components used in industries are put under very high stress. If this stress is not eliminated at the right time through various methods, the components can face frequent failure, which will cause huge economic losses to the industry. Additionally, it can also cause severe accidents claiming many lives of workers, who work in the industry, as well.

When choosing the electrical accessories, you must be careful and choose only the best quality electrical accessories for your industrial electrical network. One such accessory is the stress control tubing. The stress control tubing is used for eliminating excess of electrical stress exerted in the high and medium voltage cables. They eliminate the electrical stress from the insulating screens and straight through cable joints, and hence are used near the cable jointing and termination kits.

Compaq is one of the best stress control tubing manufacturers providing a wide range of stress control tubing made from high grade radiation cross linking polymer, which allows them to operate under a wide range of temperature from -400C to 1000C. Compaq stress control tubing can work under loads up to 36Kv and have a very low shrinking temperature of 1000C. Here are given some of the technical information about Compaq stress control tubing.

| Properties | Value | Standard |

| Physical | ||

| Tensile Strength | 12 Mpa (N/mm2)(min) | ASTM D638 |

| Ultimate Elongation | 300%(Min.) | ASTM D638 |

| Longitudinal Change | +10% (max.) | ASTM D2671 |

| Thermal | ||

| Accelerated ageing | (120oC for 500 Hrs) | ASTM D2671 |

| Tensile Strength | 10 Mpa N/mm2 (min.) | ASTM D638 |

| Ultimate Elongation | 300% (Min.) | ASTM D638 |

| Low temperature flexibility(-20oC for 4 Hrs) | No Cracking | ASTM D2671 |

| Heat Shock (250oC for 30 Min.) | No Cracking or Flowing | ESI 09-11 |

| Shrink Temperature | 1250C | IEC 216 |

| Continuous Temperature Limit | -40oC to + 100oC | IEC 216 |

| Electrical | ||

| Volume Resistivity | 1 x 107 Ohm.cm(min.) | ASTM D257 |

| Dielectric Constant | 15 (Min.) | ASTM D150 |

From many years, Compaq has been a trusted provider of high quality electrical components and accessories for many big industries in India and overseas.