When it comes to choose the best materials for your business equipment, the variety of options in the manufacturing industry can confuse you. Most people choose alloy steel when it comes to choose the best materials for their business equipment. Alloy steel is a great material for all types of business equipment. It is basically steel which is combined with other types of elements so that its mechanical properties are improved. The quality of alloy manufacturing mainly depends on its combination and the variation in the combination should be between 1% and 50% by weight.

Why Alloy Steel is a Superior Material?

Typically the alloying materials are combined in such a way so it achieves certain properties in the alloy steel. A combination percentage of less than 5% can help achieve a good strength and durability. Alloy steel is superior since it is corrosion resistant and can sustain to extreme temperatures as well. Apart from that, alloy steel has certain qualities that make it stand apart from its competitors. Therefore, it is a good choice for using in heavy duty machineries as well as equipment. Some of the most common properties that make alloy steel superior are – resistant to corrosion, high strength, durability, wear resistance, toughness etc.

Uses of Alloy Steel:

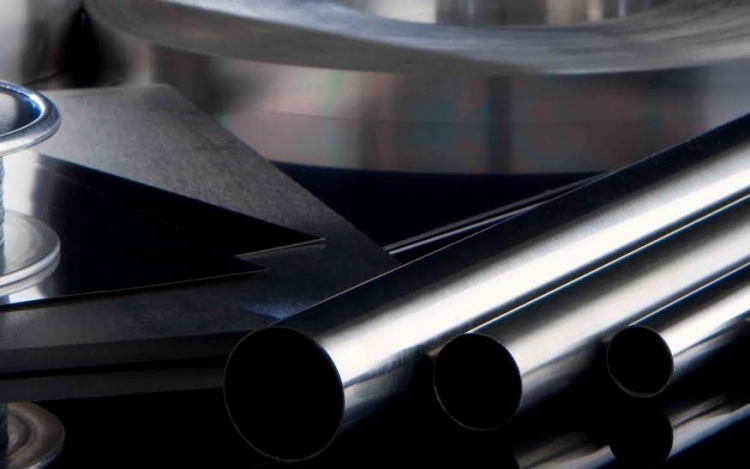

As mentioned earlier, alloy manufacturing is very popular around the world since people use alloy steel for many purposes. For e.g. alloy steel can be used in manufacturing several business equipment like pipes and tubes, wires, round bars, sheets and plates, outlet fittings, weld fittings, and others. All of these equipment can be used in a variety of industries – both big and small industries. Alloy steel is so durable that it can even be used for high demanding application, thus making them ideal to use in heavy industrial applications. Besides, alloy steels are mainly used in electric motors and transformers.

Why to choose Alloy Manufacturers?

Alloy manufacturers are widely available around the world and when it comes to avail alloy steel, it’s good to go for the alloy manufacturer. Alloy manufacturers know how to properly combine the elements in an alloy and based on the elements used in the alloy the alloy steel is mainly classified into two categories – high alloy steel and low alloy steel. Some of the most common materials that are used as a combination in alloy steel are nickel, chromium, molybdenum, silicon, boron etc. Sometimes, some not so common materials like aluminum, cobalt, titanium, copper, zinc, tin, and lead can also used as a combination in alloy steel.

There are few reasons why you should choose alloy manufacturers when it comes to avail alloy steel for your business equipment. First, the manufactures have their own integrated engineering facility with traditional machines. As a result, the manufacturers can ensure the fastest delivery possible.

The experience matters a lot when it comes to avail business equipment. Since the alloy manufacturing companies have years of experience in various manufacturing areas, they well understand your requirement and can excel at the fastest and highest quality delivery.