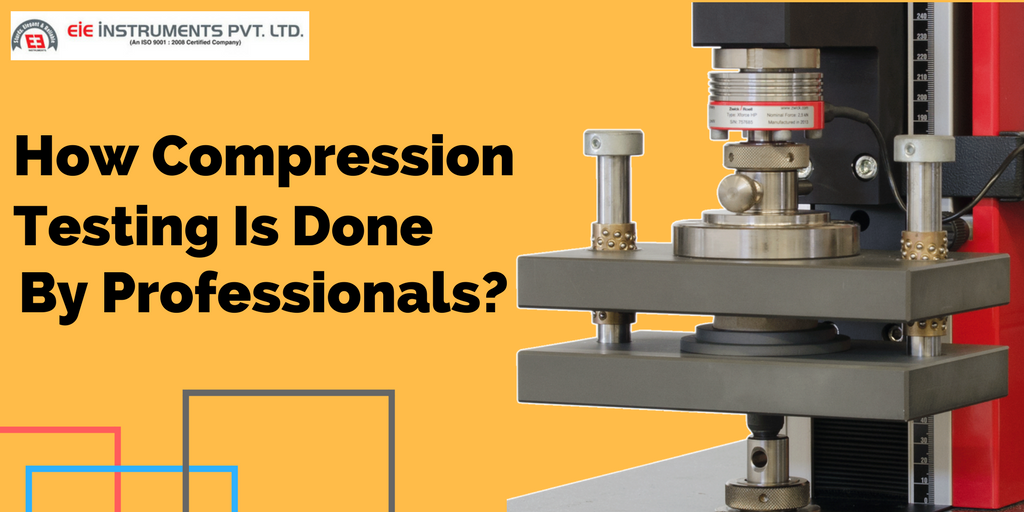

Professionals select numerous uniform test specimens while preparing for compression test to avail accurate comparative results. A compression testing machine is used to perform the test. Grip selection is important for experts to ensure reliability of results and test accuracy. There are several specially designed grips used to ensure consistent test performance, minimal sample movement, and reputability.

How the Compression Test is Done?

Experts apply a constant test speed when applying load to the specimen and a motorized test system will ensure a consistent rate of deflection. Cross head speed has to be slow to capture a reliable compression profile of the material, but fast enough to complete testing within a limited time period.

Guidelines To Operate Concrete Compression Testing Machine

For a specimen, which is unlikely to break, the test method should mention at what moment to take a measurement reading. Usual test procedure conducted for identifying the characteristics between deformation and load of a specimen may be defined in following four steps-

- Put the sample on the bottom platen of the testing machine. Make sure you place it at the center.

- Lower the platen until it contacts the sample top.

- Reset the readings of systems to measure the distance between the bottom platen and compression platen. Start the compression test at a uniform speed to a predefined distance or until your sample breaks.

- Back to the start position.

For comparative results, you may repeat the tests and ensure statistical significance of results.

Results

Once the test is complete, you have to see the results. You need to store, export or analyze the results as per the requirement of the application. If you have computer-operated testing systems and automated systems, you can avail the facilities for transferring the results to a personal computer, data logger or printer.

You can perform compression tests for various applications. If the test is performed correctly, it will yield huge information with which you can maintain quality in the tasks.

Some tips for techs-

- You can undertake compression test as part of the design process, in the lab or production environment.

- You can use it to evaluate consistency of manufacture or safety evaluation or quality check.

- Tester will measure two basic quantitative factors in the test, i.e. deflection and load.

They use specialized testing machine for performing the tests. If you need details on the digital compression testing machine, you can talk to the makers of the product.